How To Repair My Plasma Cutter

WARNING: Plasma cutter maintenance and repair should only be attempted by those skilled in electrical troubleshooting. Plasma cutting systems utilize high voltage and direct-current (DC) electricity. Electric shock can injure or kill.

Symptom

The torch fails to initiate the cut arc when all other conditions for normal operation are correct—power supply energized, safe and parts-in-identify interlocks satisfied, gas pre-flow at torch, and torch within transfer distance.

The sequence of operation for the typical plasma cutter is as follows:

- The beginning-cutting betoken is sent to the ability supply to energize the system.

- A solenoid opens, allowing gas flow to the torch.

- The pilot-arc relay latches, activating open-circuit voltage (OCV) between the nozzle (+) and the electrode (-).

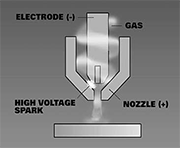

- A high-frequency (HF) spark (run into illustration 1) is supplied to the torch past a loftier-voltage generator with 3,000-10,000 V AC output. The loftier-frequency generator usually includes a loftier-voltage transformer, capacitors, spark-gap associates, and coil.

- The high-frequency spark ionizes the gas flowing through the torch, making information technology electrically conductive. The ionized gas allows current menstruation betwixt the electrode and nozzle. This current is limited to 20-xl A DC past the pilot resistor.

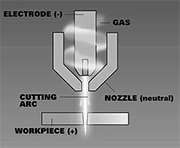

- The arc blows out of the orifice and reattaches to the face up of the nozzle, forming a pilot arc (encounter illustration 2).

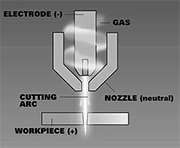

- The pilot arc forms the electrical pathway to the workpiece. If the torch is within transfer distance, unremarkably 0.25 to 0.fifty inch from the material, the pilot arc will transfer to the plate since the plate is connected to the positive pole of the DC circuit and is not limited by a resistor (run into illustration iii).

- A current-sensing circuit senses arc transfer, shuts off the HF generator, and opens the pilot-arc relay.

In simple terms, the torch needs three ingredients to form a pilot arc:

- Plasma gas

- DC ability

- AC high frequency.

With any of these ingredients missing, the torch will not burn down, transfer, or cut.

Illustration 1

Illustration 2

Illustration 3

Troubleshooting starting bug

When starting problems occur, the operator should kickoff evaluate the pilot arc. He raises the torch several inches above the textile to provide a skillful, clear view of the torch. He and so signals the torch to fire. After several seconds of gas flow, a airplane pilot arc should form at the torch. A healthy pilot arc will sustain itself in the air for several seconds. He looks for an arc with a vivid white-blue color that projects 0.25-0.l inch from the end of the nozzle. The arc should non spit and sputter or audio raspy; it should be smooth and steady. He should examination the pilot arc a number of times in the air to see if the condition repeats.

Problem ane: Hard starting

If the airplane pilot arc spits and sputters but fires intermittently, the problem may be difficult starting. Hard starting occurs when the HF struggles to break downward the high-pressure barrier between electrode and nozzle. This can be acquired past insufficient HF or excessive gas force per unit area.

Here are four steps to remedy hard starting.

- Cheque the gas pressure level and flow. The plasma gas pressure level or catamenia setting should non exceed mill- recommended settings. Excess pressure in the plasma bedchamber makes it harder for the HF spark to jump the gap, so that the pilot arc is finer blown out earlier it can fully establish. High-gas pressure accounts for the majority of hardstarting issues, and is often overlooked— a zealous troubleshooter might replace every component in the pilot excursion, merely to observe the air pressure had been turned too high.

- Clean the hoses and wires that comport gas and power to the torch, and inspect them for visible damage or loose connections. If the shielding is covered with dirt, metal dust, or moisture, the high-frequency free energy can be dissipated. Blow off the leads with an air hose or wipe them downward with a clean cloth. Eliminate whatever coils in the leads—they can crusade a large inductance. Insulate the leads from the cutting machine.

- Inspect, clean, and regap the spark-gap associates. High frequency from the high-voltage generator is unremarkably sent to capacitors that discharge the electricity beyond a spark-gap assembly. Over fourth dimension the spark-gap electrodes tin can deteriorate or become contaminated with metal grit and dirt. Make clean and re-gap the electrodes to the manufacturer's specifications. Gap should exist 0.015 to 0 .030 inch, depending on the organization.

- If using a water-cooled torch, check coolant resistivity. For near systems it should be less than 10 Kohms/cm or 10 micromhos.

Problem ii: Weak, blue spark at torch

If in that location is a visible spark at the torch but it is a small blue spark that looks similar to the spark at the spark-gap points, then the pilot arc has high frequency merely no DC component. The most probable causes for loss of DC in the pilot arc are worn contacts or a bad coil in the pilot-arc relay; or a defective airplane pilot resistor.

Trouble iii: No spark visible at torch or at spark gap

No AC power to high voltage generator; lacking high-voltage generator; defective capacitors; shorted or damaged spark-gap assembly.

Problem four: No spark at torch, spark at spark gap, astringent difficult starting

Refer to problem ane; shorted or open torch lead; shorted or open connection in torch body.

Source: https://www.hypertherm.com/learn/articles/pac-systems---starting-problems/

Posted by: colepliteard.blogspot.com

0 Response to "How To Repair My Plasma Cutter"

Post a Comment